THE toughest part of selecting the right filler metal for any application is that, often, there is more than one right answer.

In aluminum trailer and truck body manufacturing, the task is much simpler because the list of choices that can be used in this application is significantly reduced. The most common base materials used include:

Extrusions – 6XXX series, such as 6061.

Plate – 5XXX series, such as 5052 for dump/sheet trailers and 5454 for tanker or dry-bulk trailers.

Additionally, the selection process for the trailer industry has some basic requirements to be considered. These are based on two major factors:

Aluminum trailer and truck body welds require strength—specifically tensile and shear strength.

Almost all aluminum trailer designs involve a 5000 series (5XXX) plate welded to itself, or to a 6000 series (6XXX) extrusion.

This helps narrow the field. The vast majority of builders use aluminum filler metal 5356, and it’s often an excellent choice. It offers an acceptable level of strength, is readily available, and is weldable when used with both 5XXX and 6XXX base materials.

6000 Series Alloy Base Materials

An important point to remember is that all 6XXX series alloys are heat treatable and, therefore, their properties change when heat from the welding arc is applied. As a general rule, when welding to a 6XXX series extrusion, the weakest part of the weld will be the heat affected zone (HAZ) in the 6XXX material.

Another important point to remember is that when you design to a specific strength delivered by a specific heat treatment, that heat treatment is degraded by welding. For example, a commonly used alloy in the industry is 6061-T6. The T6 designation refers to material that was solution heat treated and aged for some time after it was formed in an effort to strengthen it. However, when you apply heat to the base material through the welding arc, the HAZ is effectively “overaged,” or weakened, by 30–40% from T6 properties.

So why do we even bother using treated 6XXX series if we’re going to weld on them? Often, from a design standpoint, the area where the improved mechanical properties are required is not affected by welding.

5000 Series Alloy Base Materials

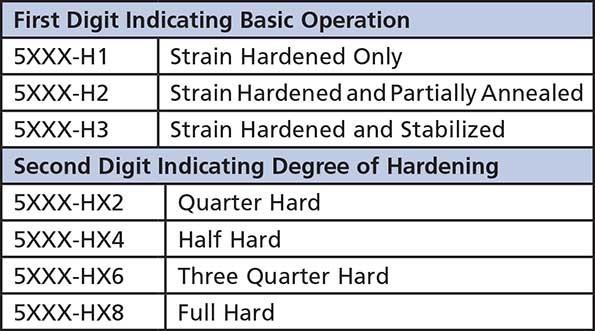

Aluminum, as cast or after annealing, is designated as “O” temper. This temper delivers the lowest mechanical properties available. It is more common to use a base plate that has been specifically treated beyond “O” temper to improve mechanical properties. A common technique for 5XXX plate is to strain-harden (that is, cold work) the material, a natural by-product of fabricating sheet metal, which is designated by the suffix “H.” Strain-hardened 5XXX base materials are commonly used in trailer manufacturing and will provide improved mechanical properties. Table 1 lists the suffix designations and the type of strain-hardening treatment. The numbers following the H suffix indicate the level of strain-hardening performed.

In trailer design, it’s important to remember that the heat from the welding arc will convert the material in the heat affected zone back to “O” temper, or back to its annealed state. All strain hardened properties will be lost, as “O” temper delivers the lowest mechanical properties. After the “H” temper is lost in welding, there is no way to gain it back post-weld. However, as with heat-treatable alloys, the improved mechanical properties typically are required elsewhere in the structure and not in the HAZ.

The Filler Metal Standard: 5356

Based on this general information, an all-purpose filler alloy used to weld plate to extrusion is 5356–-an excellent choice. It’s readily available, provides appropriate strength requirements for welding both 5XXX to 6XXX and 5XXX to 5XXX, and is cost competitive.

Specialty 5356 fillers have been developed specifically for the trailer manufacturing industry, such as Lincoln Electric’s SuperGlaze® 5356 TM™. In this case, the chemistry of the filler metal has been engineered and manufactured to provide specific welding characteristics that can improve productivity for trailer applications. These characteristics include:

Superior wetting which can allow for faster travel speeds while maintaining bead profile

Enhanced operator control with improved puddle clarity.

Improved arc stability

These features are especially appropriate for long groove or fillet welds or for large diameter circumferential welds. However, some trailer manufacturers often opt to use 5556 filler material over 5356. Is there any advantage?

If welding 5XXX to 5XXX series base materials, there is an appreciable gain in strength from using 5556. The difference between the two filler metal alloys is the amount of magnesium. The increased levels of magnesium in 5556 will deliver improved mechanical properties over 5356 and will remain after welding on 5XXX base materials. However, if your shop is welding 5XXX to 6XXX, it is difficult to find a discernible advantage to using this specific alloy, given its usual premium price over 5356. Regardless of the filler metal, the weakest part of that particular joint will still be the HAZ.

Tanker Trailers

Tanker trailers and dry-bulk carriers often use the same 6XXX base materials for extrusions. But sometimes special considerations need to be made for the 5XXX plate material used to fabricate the tank. A commonly used alloy is 5454, which is used both for tank/dry-bulk trailers and dump trailers. As a base material it delivers good strength, formability, and it’s very weldable. One other important aspect of this base material alloy is resistance to chemical corrosion. 5356 is commonly used where chemical corrosion is not a concern. However, if a particular tanker is designed to carry a corrosive substance, such as some variants of crude oil (acidic) or harsh chemicals such as sodium nitrate, 5554 should be used.

While 5356 can be used for this base material in non-corrosive applications, it should not be used in applications where chemical corrosion properties or high temperature properties are important. In these applications, the use of 5356 filler will greatly reduce the corrosion resistance of the weld joint. This is due to the higher levels of magnesium which can possibly lead to eventual failure in the field.

If this is a concern, as it might be with tankers used to transport acidic or basic substances, the best filler metal choice is 5554. This alloy is typical of 5XXX series filler, but with reduced magnesium levels over 5356, 5554 better matches the base material and maintains the corrosion-resistance properties in the weld. As a general rule, the best choice for welding 5454 where chemical corrosion is a concern is the matching filler metal, 5554.

Support

Generally, selecting the correct filler metal for your specific trailer application is not overly challenging. Understanding base material metallurgy is important in the design stage, but in North America, the trailer and truck body industry has been designing some of the most robust, fuel-efficient trailers in the world.

If you have specific questions, do not hesitate to contact your filler metal manufacturer. Some have a team of engineers who specialize in aluminum welding. As a quick reference, you can refer to a filler metal alloy selection chart such as the one found at www.lincolnelectric.com/aluminum.