The Cummins ISC diesel engine in this case a 1999 model quit suddenly on the main street just outside our shop. The driver was from out of town and we had to hold his bus for repairs. It had to be towed in and found the problem to be two engine codes. They were engine position and engine speed codes.

The engine cranked over but did not start. So using the Cummins insite lite software we can find the schematic for both of these codes with some troubleshooting information as well. There is an online site called Quickserve that is very valuable for working on Cummins engines. It requires a subscription but well worth it.

The first step we took was to check the sensors and wiring. In the past we have had trouble with one or both of the sensors being innacurate but that would only cause rough running. The engine shut down was a condition never experienced with these types of codes. Unplugging the harness at both ends of the engine ECM and the 2 sensors was in order so we could test the wiring harness for opens, grounds and shorts.

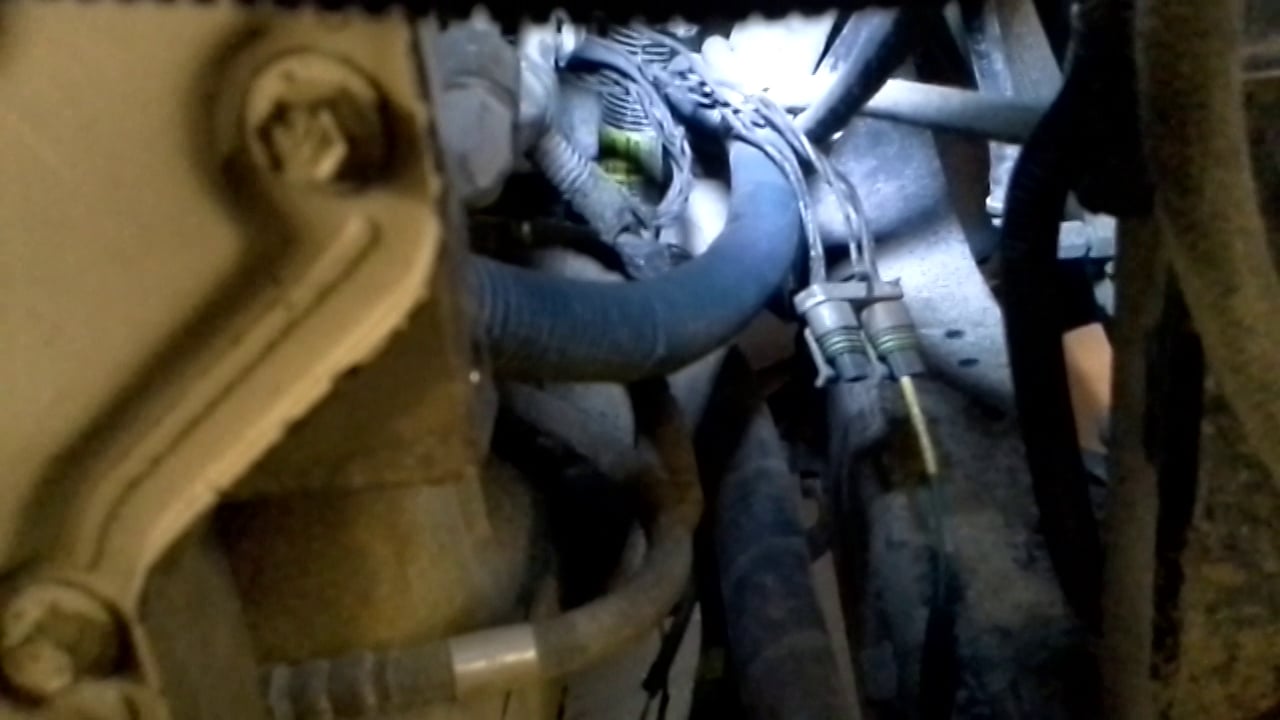

Each sensor has 3 wires. There is a 5 volt reference, input signal to the engine ECM and a return signal. We found one of the wires to have a high resistance so that gave us the go ahead to unwrap the wiring and start to find the faults. It’s very tight where the ECM is located so it was not a pleasant job. The grime trapped inside the wiring loom made this job a dirty one to say the least.

The only way to fix this wiring was to totally remove all the electrical tape and loom to gain access and repair the faulty wiring. The tight fit between the frame and engine block made access difficult. One of the wires read an extremely high resistance so we focused on that set of wiring to see what was going on.

The job is still on the go and I will be updating our results as it happens. If we don’t get right into the wiring using these methods this bus will be sitting for a long time. It will be interesting to find out what the problem is because it will help us understand why it happened and we’ll know how to avoid it from occurring again.