The Thomas HDX school buses we have in our fleet range from years 2007 to 2009 and one fault that has been happening lately is either a no start or no run condition. Of course as always everything happens in groups of three. There was a no start a couple of weeks ago that required a tow truck back to the shop and luckily the latest break down happened in the shop which was a no start featured in this video.

I’m waiting for the third bus to do the same but I’ve knocked on wood already and holding my hands together in prayer that this doesn’t happen to a bus that’s out of town or on a field trip. Since these buses are the same design on the OEM side some parts are interchangeable. The no run bus was a 2007 while this bus in the video is a 2009. We have both Cummins and Mercedes diesel engines in our pusher buses.

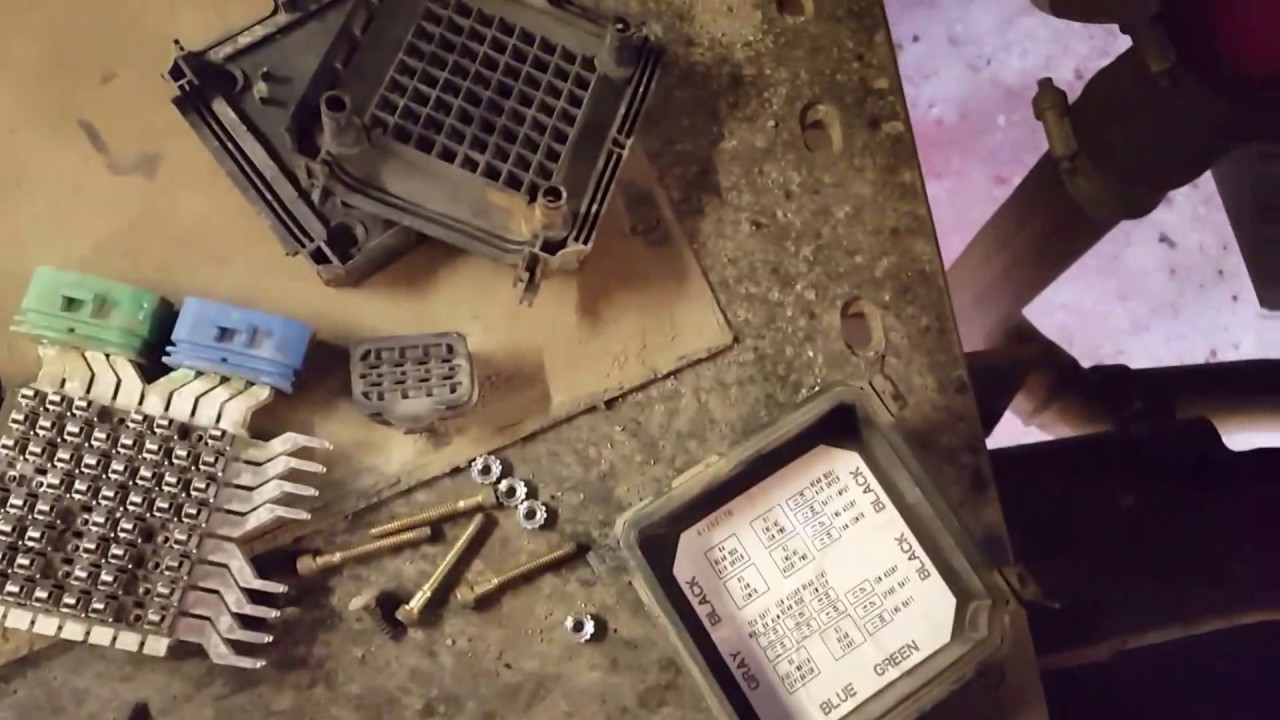

I did find a schematic for these modules which are bolted to the switch housing above the engine. They are called a VEC (vehicle electrical center) with a direct battery feed that is fused and an ignition feed controlled by a relay running directly (Mercedes) to the engine control module and the CPC (common powertrain controller). The CPC is an interface between the powertrain and OEM side. The battery and ignition circuits run parrallel to the CPC.

In the no start condition we had no continuity to the starter relay when the ignition switch was activated (Cummins ISC). With the no run problem there was only 2.7 volts feeding the Motor Control Module on the Mercedes diesel engine. In both cases the new VEC fixed the problem which leads us to check these modules a lot closer during services and yearly maintenance PMs. Most times you can spot the green corrosion developing at the terminals.

Even better we could just replace them every 5 years just to help prevent future issues. We already have component time limits on our maintenance program. Spring brake pots are replaced every 5 years, Air dryers are serviced every 2 years unless there is a premature oil build up at the unloader and so on. The cost compared to a break down on the road is well worth it.

That’s the beauty of learning from experience as in life you go through something and the next time it happens you’re memory kicks in and voila problem solved. Until next time I hope this article will help you get down and dirty on your Thomas HDX if one day it does not run or start.