The parked regeneration is a regular procedure for diesel engines that get to the point where passive regens are not keeping the DPF (diesel particulate filter) clean. The differential pressure sensors will signal the motor control module MCM to alert the driver with an amber light on the dash that a parked regen is required.

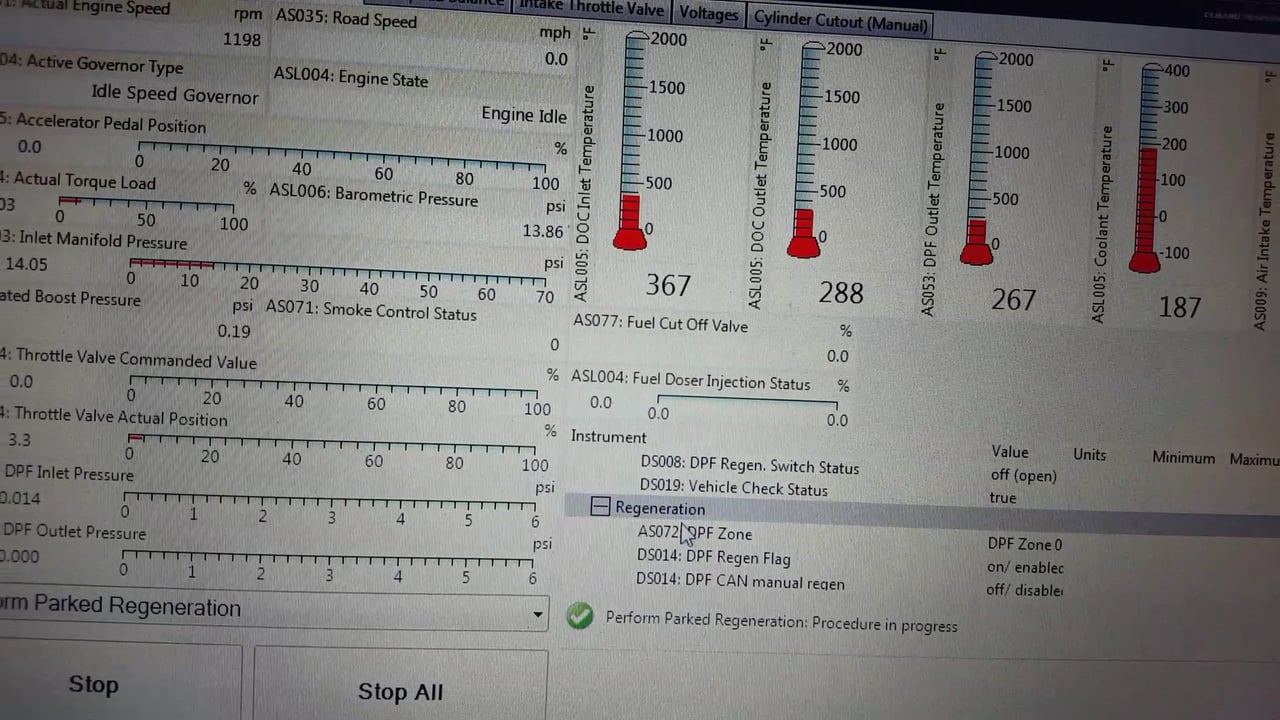

In this video you can see the Mercedes software at work. The engine has to be at operating temperature and the park brake has to be cycled ON OFF ON. There is a list of steps to check over before a regen will happen. On the right side of the page on the laptop where I check the DPF zone level there is a green check mark that I didn’t talk about in the video that says regeneration is ready to go.

Trying to keep the exhaust system cleaned out while the engine is operating is constant with emissions always pumping through the exhaust 100% of the time unlike the old days when the crankcase breather was a down draft tube to atmosphere. The tar like soot that develops on the intake and exhaust systems require high heat to break it down and get it removed.

When the Mercedes diesel MBE 900 goes into the regen mode the engine RPM bumps up to around 1200 and diesel is injected from the doser valve down the exhaust piping while the intake valve closes enough to create high heat. When the mixture hits the DOC (diesel oxidation catalyst) a reaction occurs to remove harmful oxides of nitrogen. The more heat generated the better to melt down the soot and ash.

Another possible way to keep the exhaust system cleaned out is to drive at highway speed for at least 20 minutes. Cummins recommends this even when the DPF warning light comes on and there’s a possibility this will cause the light to go out. The high speed and heat developed might be the only step to take saving time not having to do a parked regeneration.

This week alone we had 2 buses with MaxxForce 7 diesel engines go through the DPF warning light flashing which means the situation is getting critical to do a parked regeneration. One of the buses was a wheel chair bus that absolutely could not stop for the half hour regen. We had to take the driver a spare bus and do the swap. When we got there the light had gone out but after bringing it back to the shop it went right into a parked regen using the ServiceMaxx Pro software.

The second bus was able to park and push the regen button on the dash. After the time was up the driver brought the bus home without any trouble. A wheel chair bus is at risk to having more trouble because of the in town stop and start without a lot of highway driving. The heat level does get up to where it should be fast enough so the exhaust can’t naturally clean out the exhaust system.

The software for each diesel engine in our fleet is invaluable and we would be lost without it. Reading codes and working with the emissions system requires the latest version of software to properly troubleshoot problems. I can guarantee there will always be troubleshooting with emission controlled diesel engines because they are far from perfect.