With safety being the main concern on school buses it’s important that drivers help us with our preventive maintenance program by keeping an eye on their bus with daily pre-trip and post-trip inspections. They are the eyes and ears that the shop depends on to catch problems when they happen between regular services.

Drivers have to start with a walk around and have a look underneath the chassis for any obvious defects. They check the interior, lights and air system including a brake check. At the present these checks are entered into a daily log book that they have to sign. If there are no defects they sign off with the date. If there is a defect it has to be noted and the driver signs the bottom stating that the bus is safe to operate.

If there is a clearance light out for example that’s something that allows the driver to carry on with the run. They just have to mark the defect down and sign the bottom of the log book and check off safe to operate. On the other hand if there is an air leak in the brake system they do not sign off. The defect has to be noted and nothing is signed until the air leak is repaired.

The Electronic Vehicle Inspection Report

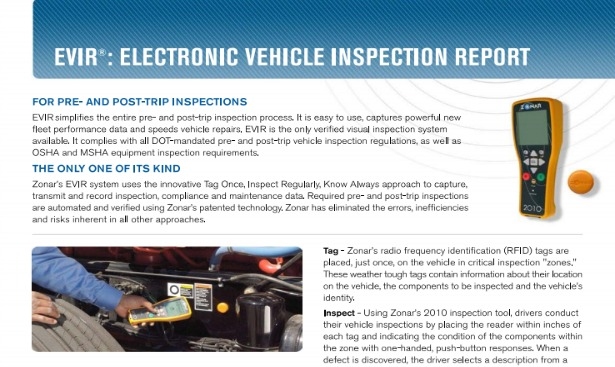

This paper system has been around for some time now and I wanted to cover a new electronic device that automatically records driver inspections with the press of a button. Zonar has come up with a tagging system that transmits all of the driver reports using a radio frequency. These tags are strategically placed on the outside of the bus pre-loaded with their location on the body and what areas have to be inspected. The bus identity is also logged during this process.

The driver holds the reader device close to the tag and specifies what components are being inspected and their condition following the prompts on the reader screen. When drivers find a defect they choose from a list of descriptions to explain the defect then they indicate on the reader if the bus is safe to operate.

Once the inspection is complete the driver places the reader into the vehicle mount. The information is automatically sent to a secure database where it can be accessed through Zonar’s own online application.

The paper trail is an OK method using log books but the work involved to keep records is enormous. Running a fleet means DOT vehicle audits and keeping maintenance records accessible to keep up with preventing break downs and high operating costs.

The EVIR cuts down on inspection time and uses time stamps for driver hours of operation. I can see this system paying for itself in no time and catching defects much more quickly than the old paper trail technique.

If you have any experience with this system please comment below and share this post if you got some value out of it.