This step involves replacing and torquing down the main bearings on a DT MaxxForce diesel engine. The main reason for replacing the bearings is to bring the crankshaft end play back to specs and replace the washed out original bearings. Some of them showed discoloration so we didn’t want to take a chance. The coolant in the oil did the damage on the cylinder liner and also the connecting rod and main bearings.

The end play is supposed to read .006 to .012 inches. Using a magnetic base dial indicator will give an accurate measurement. We originally had a reading over this spec so since the rear #7 upper bearing shell controls the adjustment replacing all of the bearings will remedy any kind of doubt. To measure end play the magnetic base is attached horizontally with the dial indicator contacting the crank which is pried front to back with a bar.

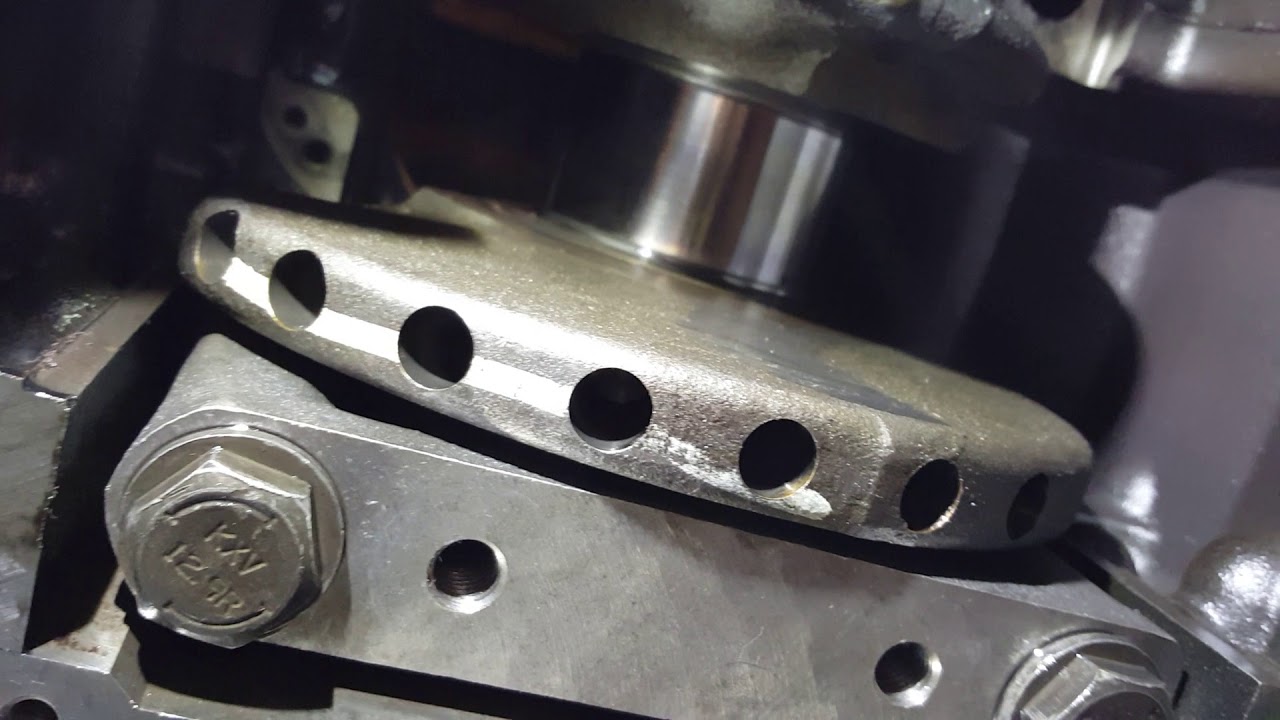

The torque on the 7 main bearing caps is a 2 step process followed by a 90 degree final torque. The torque pattern is circular starting from the middle and working your way to each end of the block. This gives an even setting compared to starting from each end and working inward which doesn’t make sense. The first torque is 100 foot pounds, the second one is 130 ft lbs and finally the 90 degree rotation of each main bearing capscrew.

The main bearing caps are numbered with a reference on the block as well so there is no way you can mix up the bearings cap or install them 180 degrees out. I can remember having to number stamp to make sure the rod caps and main caps were put together exactly the same way they came off apart. The connecting rods are cast as one piece and then cracked apart so they will only fit one way.

The plastigauge testing to check the new bearing to crank wear turned out good. We had an average of 1.5 to 2 thousandths of an inch clearance on the main bearings. This crankshaft has a lot of life left depending on keeping coolant out of the engine oil. I’m planning to send out oil samples sooner so we can monitor any sign of coolant in the oil.

If there is coolant loss reported by the operator we will take an oil sample and get it analyzed right away to prevent this premature wear issue we’re experiencing now. It’s a lot of labour and money to do a rebuild these days and preventing this type of thing happening allows us to focus on keeping our buses on the road instead of weeks of down time sitting in the shop. This takes one tech away from regular PM work and plugs up a bay in the shop.