In 2008 we purchased an International CE school bus with a MaxxForce 7 diesel engine. It also was a hybrid that operated up to 50km per hour. The idea was to assist the launch out of the gate then going full diesel after the 50km per hour speed was met.

It worked fine for a few years but finally the batteries gave out and it was instantly transformed to a standard diesel engine. The hybrid manufacturer could not find a hybrid battery pack that could do the job.

Fast forward to the present day and we’re looking at an engine code that causes a no power problem. The fuel rail pressure is not showing up using the ServiceMaxx software. Usually you can hook up and read actual fuel rail pressure and desired fuel rail pressure. All we see is an “error” in the field box that should give us the pressure reading.

The “On Command” site offered by Navistar is a great resource with manuals, work history by the dealer and a cool section called “iknow” that you can search with keywords to find a related repairs that matches yours with procedures and solutions. For example if you enter dpf “diesel particulate filter” any job that dealer techs have encountered shows up.

This really saves a lot of time when you can find an instance similar to yours with information that goes through the proper steps to make the repair or troubleshoot the fault. “On Command” also has a master service manual that can narrow down the information you’re looking for like locating fuel injection parts or component disassembly procedures.

I like to go through how a system operates first before tackling a job. If you don’t know what makes a component or operating system tick it’s a hard road to troubleshooting and repairing a problem. Using these resources helped us locate the fuel rail pressure sensor since that sends the pressure signal to the engine ECU.

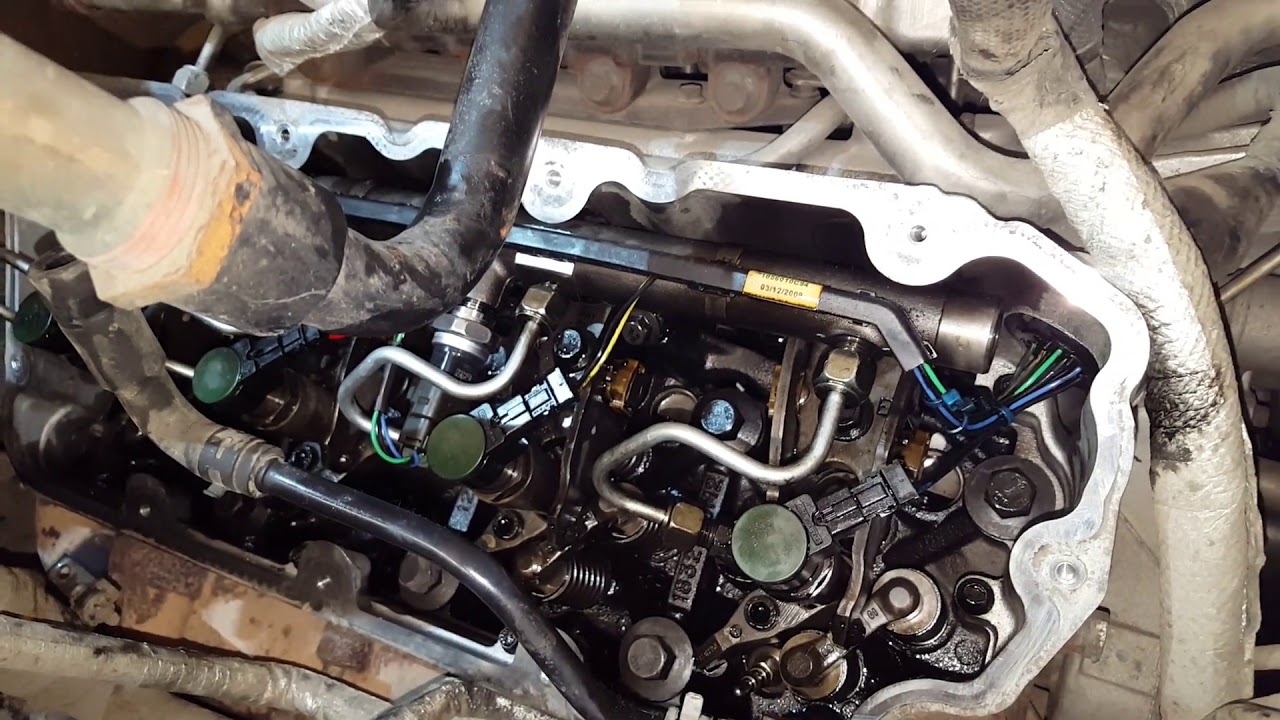

It’s located under the right hand valve cover. One disadvantage to working on a MaxxForce 7 is the accessability to the base engine. There’s a lot of hardware above the valve covers so you’ll have to go through some extra parts removal to get to it. The video shows where we’re at right now so I will keep updating as things develop.

At this point we have replaced the fuel rail pressure sensor and reassembling the engine so it can be fired up and retested for the fault. Getting a fuel rail pressure signal this time will make a big difference with performance. It’s deceiving sometimes when the engine does not get a signal it will derate as it’s programmed to do and not an actual mechanical problem but an electrical fault.