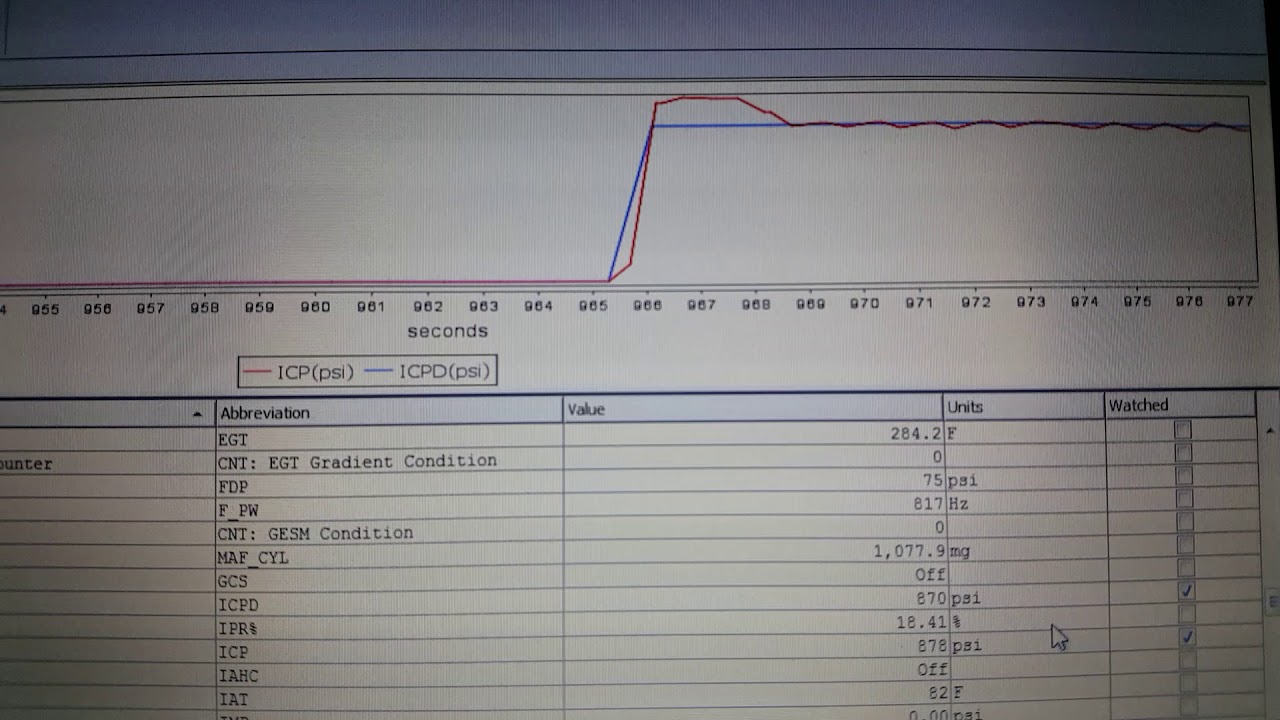

This running test for injection control pressure (ICP) is a good test to run since these specs determine the fuel injection operation. This is the DT MaxxForce which requires 870 psi of ICP to run while the maximum can go as high as 4500 psi. These high pressures create problems if there is a leak in the high pressure manifold or anything else related in the system. The HPOP (high pressure oil pump) supplies the high pressure engine oil to the hydraulic operated injectors so if pressure drops the injection system will fail or run poorly.

Our shop has had some experience with low ICP which can be mechanical due to a faulty o-ring on an injector or high pressure manifold. One step for troubleshooting is applying shop air to the high pressure manifold which eliminates the high pressure oil pump all together. Shop air usually runs around 120 psi so when that is hooked to the manifold inlet the leak will be obvious most times. An ICP pressure sensor code will fool the engine computer with an incorrect reading which will derate the engine.

Working with high pressures causes problems and seeks out all of the weak spots. With emissions the goal is to create high pressure fuel injection so combustion is cleaner reducing carbon and soot. We are comfortable with the troubleshooting process on these systems but it takes time. The steps to get to the parts on the injection system adds down time due to the difficulty of removing the valve cover and high pressure manifold.

Most emission controlled diesels have an array of harnesses and lines in the way when it comes to disassembling the top end. Two to three days is not uncommon for repairs to be completed. The cost could be excessive if injectors or sensor replacement is required. We are constantly dealing with engine codes when ICP pressures are not within the parameters. The one advantage for us is we have dealt with all associated issues since they tend to repeat themselves.

Since there is no way we can bypass these faults and since they happen repeatedly the repair times are improving. Our tooling for repair is up to date and repair manuals are close by to help us out. Experience gives us the confidence to keep up with these repairs and maintenance is adjusted to improve operation and reduce break downs. It’s another chapter in the school bus garage.