This is one of the many important steps along the way towards rebuilding our MaxxForce DT diesel engine. If you’re following posts here you’ll notice a steady flow of articles regarding these engine models. As I have mentioned before there’s a lot of flaws in engineering that is causing premature wear and necessary in-frames to keep the bus on the road. Although the expense and labor is excessive to carry out this job it has to be done. Not keeping a school bus on the road that cost well over one hundred thousand dollars is definitely not feasible even though we will be putting out over 10,000 dollars in the process.

So there’s no need to gripe about this situation which sometimes I will admit does happen from time to time just to vent. It’s better to move on and deal with problems since that’s the job we have been given. I knew what I signed up for and fixing things is in our job descriptions so of course there will be frustration. The key is to stay calm and systematically carry out repairs, maintenance and troubleshooting.

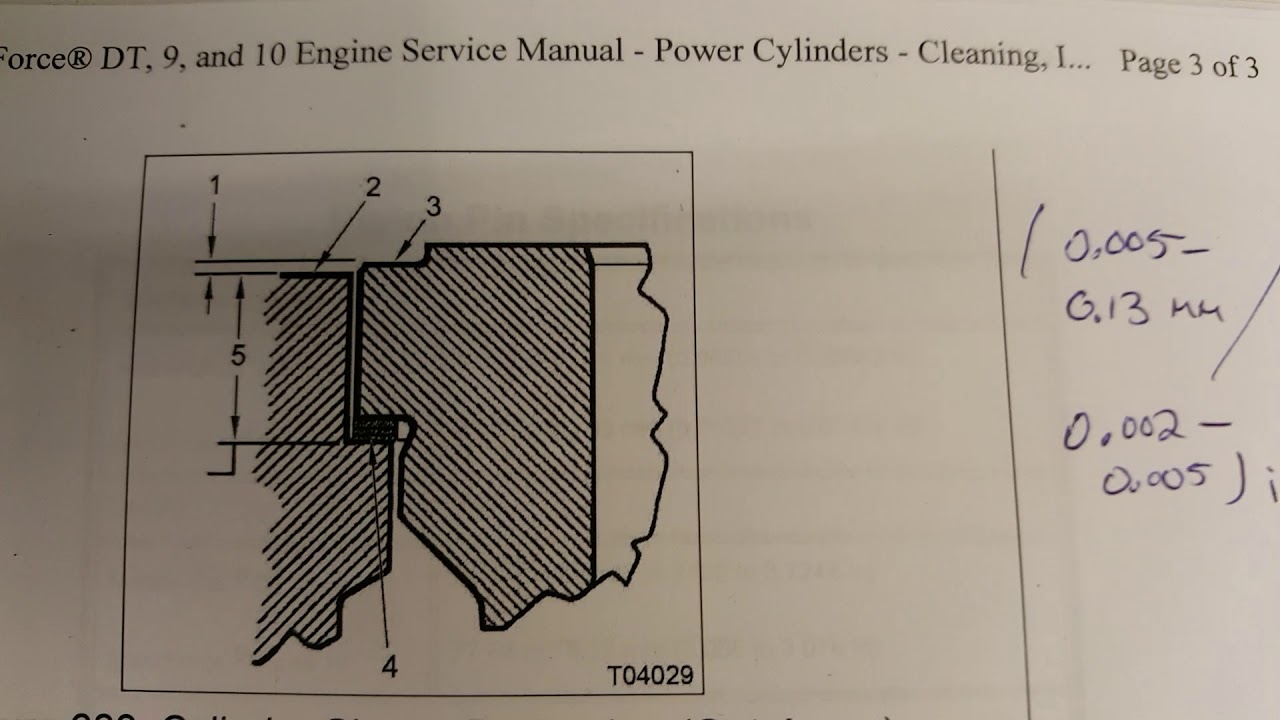

The video shows the dial indicator measuring the cylinder liner protrusion. Every liner has to protrude between 2 and 5 thousandths of an inch. The variation between all six liners must not exceed more that one thousandths of an inch. If there is not enough protrusion we would have to shim underneath the liner shoulder to bring it up to meet specs. The proper protrusion ensures a good seal on the head gasket.

Many years ago I worked up north in a truck shop which was a Cummins dealer. I was 20 years old and rebuilt my first diesel engine…a Cummins 350 NTC. The liners were also replaceable and like the MaxxForce had to be measured and shimmed. Many times I had to cut the counterbore down and add liner shims on the Cummins models. So 40 years later technology has not changed in this area.

The MaxxForce engine liners have to have the hold down clamps to get a proper dial indicator reading. The o-ring on the liner is the only thing separating the coolant from the crankcase so care has to be taken when installing them. Replacing liners saves a lot of money and down time considering the alternative which requires removing the engine and either replacing it or repairing the worn cylinders if that’s possible. It would need to be totally stripped down to the block for repair. The manufacturer would need to supply cylinder sleeves which are pressed into the worn cylinder. A machine shop would have to carry out this kind of work. In the end it all works out.