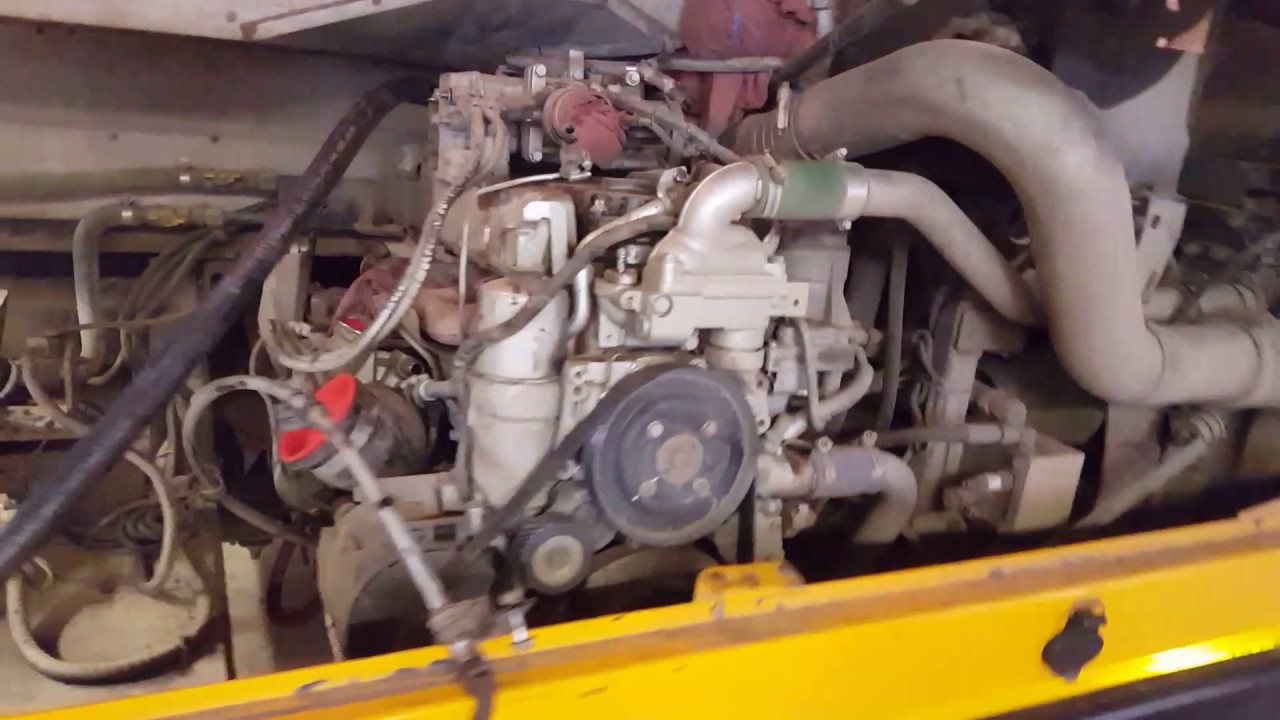

This school bus with a Mercedes MBE 900 diesel engine suffered a premature air compressor failure due to dirt in the engine oil caused by a faulty air intake hose. We had already replaced it a year earlier. The engine oil sample that I receive by email indicated a severe level of dirt in the oil. The next step was to check the air intake ducting, hoses and connections.

Sure enough the corrugated plastic hose that feeds filtered air to the air compressor had a crack that allowed unfiltered air to flow to the air compressor prematurely causing wear and eventually taking out the cylinder and pumping oil into the air brake system. An obvious sign is excessive oil at the air compressor discharge unloader valve.

Something like this is disheartening because it should not have happened. The plastic hose was inferior and since then we have replaced it with one inch black heater hose which is the normal type of hose used. Now we are replacing all of the OEM hoses on these models to avoid another failed compressor which costs $1200.00 dollars before the tax man.

As far as the engine goes it would draw dirt into the intake system when the air compressor was not operating in the discharged state. I will have to see the next oil sample analysis to see if there is a change with contamination levels and no increase in metal indicators from the engine components. It’s unfortunate but hopefully the diesel engine side will not suffer from this failure.

The operator also reported he was adding coolant on a daily basis before we investigated which was caused by the compressor head gasket failing and producing a dripping coolant and oil mess out of the air dryer unloader. The mud flap directly below the dryer unloader was stained with coolant and oil. This is good news in a way because the alternative loss of coolant would be the engine cylinder head or gasket being the cause.

There was also oil in the coolant so the coolant fill tank (surge tank) was black. If we don’t have to do anything further after the compressor is replaced I would be relieved considering the amount of work it takes to remove the cylinder head on one of these engines. The very small area of the compressor would wear much faster compared to the inline 6 diesel engine.

Not only will we be replacing the air compressor the air dryer will also be serviced along with new engine oil and filter.

With all this being said if we did not have an engine oil sample program and this bus kept running the dirt contamination would have taken out the engine over time. I always read all of the sample reports when they arrive in my email inbox. A few minutes reading these reports is well worth the time especially when they indicate a critical level 4.