I do a quick tour of our garage on occasion to show you some of the jobs we do on a day to day basis. The jobs are common with a brake job, coolant leak and a water pump leak etc. Actually the reason I started blogging back in in 2006 was to show the world online what goes on in a school bus garage. At my 20 year class reunion there was a fella there who worked for the local Kenworth dealer and he thought all we did was oil changes which he said with a a light sneer on his face.

When you’re proud of what you do for a living and getting smack from the public full of mistruths means it’s time to do something about it. Low and behold Blogger was available from Google offering a free website for bloggers so that was the start for me posting photos and ‘how to’ content on repairs and maintenance on our bus fleet. The response was positive which kept me motivated. The biggest motivator was helping people with a problem and getting a thank you for helping them out.

The shop tour in this video is covering several issues. The brake job on a 2006 C2 is a typical repair every 3 years or so since brake linings can not go less than 8 millimeters. Our rule of thumb is 10 to 12 mm to be safe. Considering a brake shoe costs $23.00 each and the drums are $100.00 each (approx.) this is a cheap fix. The brake parts for buses and trucks being aftermarket are cheaper than automotive vehicles.

The International bus with a coolant leak is a weak spot which was caused by a defective coolant hose. Realistically a heater hose should last 10 years but if parts are being manufactured cheaply for mass orders I can see that as being a factor. As you can see in the video we replaced the plumbing with heavy wall brass and cast iron fittings. On 2 occasions the hose failed while the bus was enroute so there was a pool of coolant on the floor under the driver’s feet.

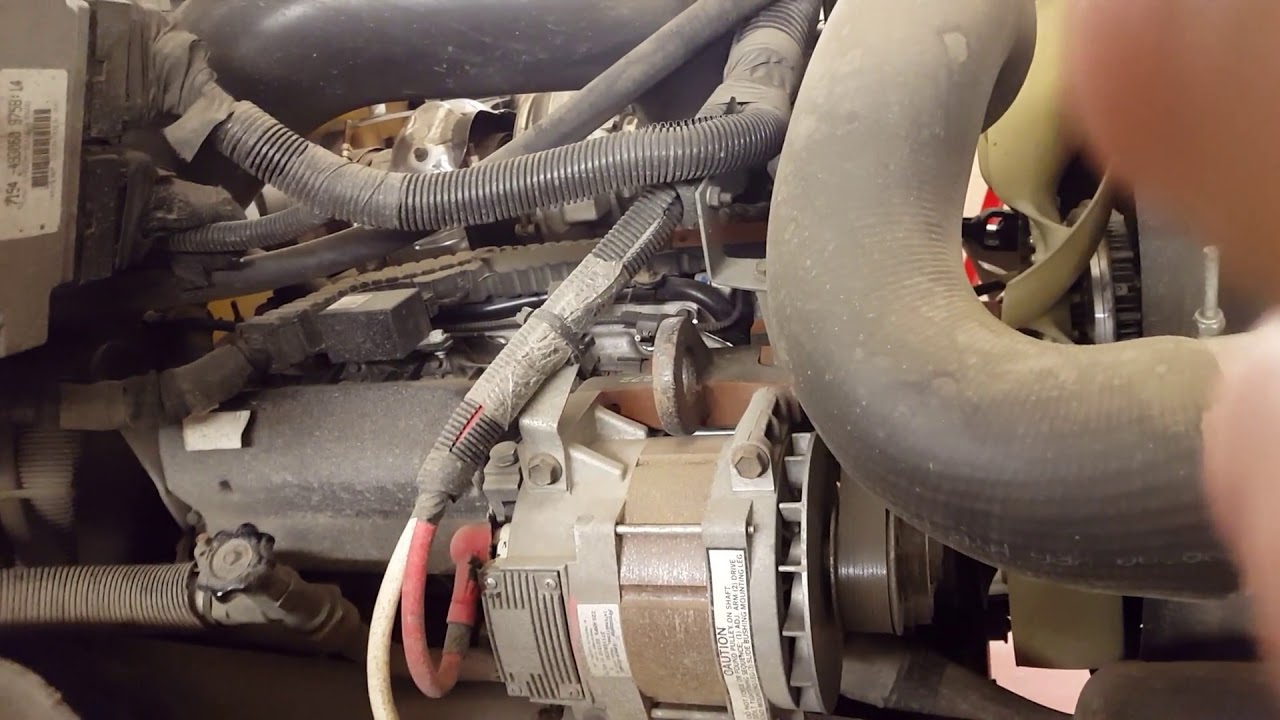

The water pump on the Mercedes diesel engine was removed because of a leak between the pump and the block. The leak was noticed by the driver which is important for us when the eyes and ears of the bus operators help the operation detect defects before they turn into major issues. That is why preventive maintenance is the operative phrase all around.

Finally the Chevy Express van with the brake repair. Every service we check the brakes especially since these vans are used mostly by tradesmen who tend to overload them. There are no exceptions and if there is any doubt the wheels come off for further inspection. None of the guys in our shop like to take chances so the extra checks on the driveline and running gear is totally exceptable.

I hope you enjoyed the tour and understand why I have to blog. Sharing our experiences is an important step to help the public understand what we do behind the garage doors.