Now you can see my cubicle where I run the fleet with various resources. Drivers will walk by and verbally inform me with defects on their bus which they also report using their pre-trip and post trip paperwork. We rely heavily on the drivers to report any problems to the shop to keep defects from escalating. When a fleet performs in-house motor vehicle inspections records must be kept on file for eighteen months. Driver trip inspection reports with defects are retained on file as well. The CVSE (commercial vehicle safety enforcement) audits us every year at the end of June on everything related to maintenance.

They allow a certain percentage rate of failure for fleets carrying out their own motor vehicle inspections. Too many violations means the privilege is taken away and all motor vehicle inspections have to be done at a retail shop. I can’t imagine taking all of our fleet vehicles to a truck shop one by one for inspection. The cost would be significant especially if a defect is found and has to be repaired before the inspection pass decal can be applied. With shop rates around 130.00/HR our budget would take a big hit.

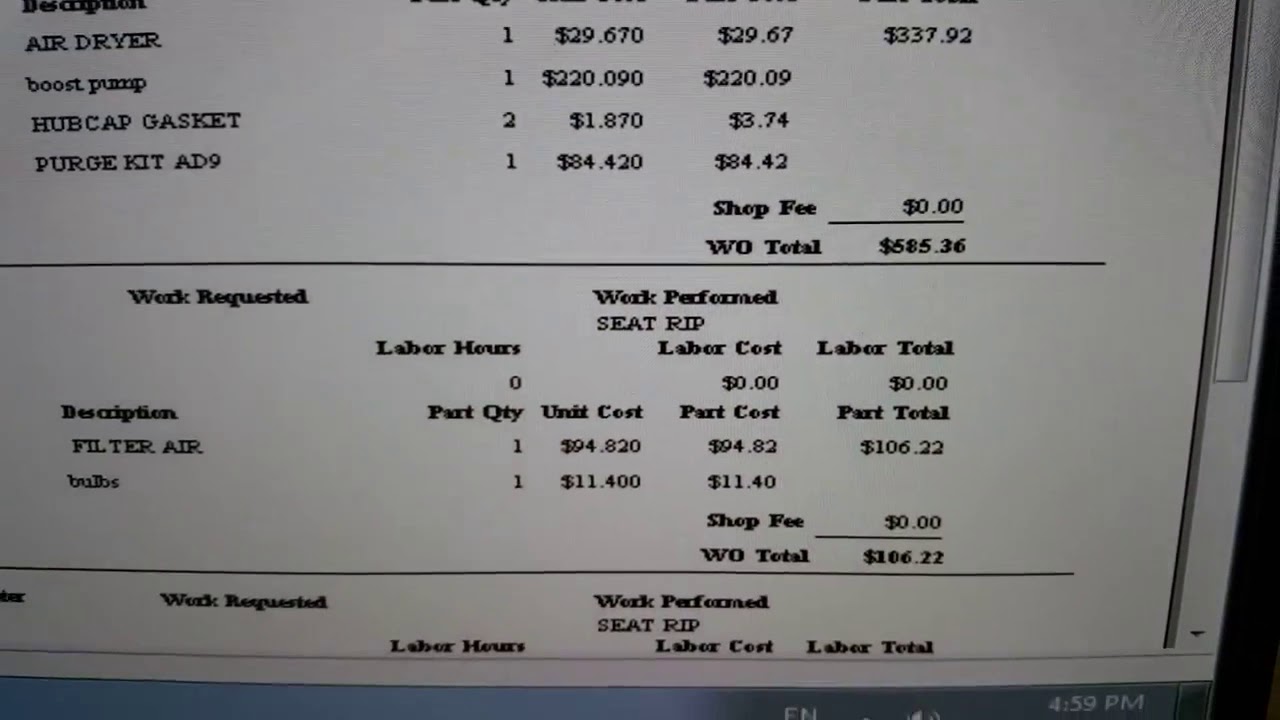

Fleet Vision software that I demonstrated in the video is essential to keep track of our preventive maintenance program. It saves vehicle maintenance history for several years. This helps us when checking back for previous repairs and parts used. To save time it’s handy to get part numbers so ordering is easier for us and the vendor. We also have our log books that the Mechanics record repairs carried out which helps in the troubleshooting process. When you know the history on a vehicle it can lead to an easy fix because of a possible defective part replaced in the past.

There is also a large white fleet to maintain that is included in the software and log book system. It’s a great resource… for example when checking for the last brake job because of something regarding brakes that is noticed during a service. Pulsating front brakes for instance would lead to checking the history to see when the last replacement occurred and if we need to talk to the driver or look in to another brand or application specs. So it’s a busy little office cubicle where I spend a lot of my time ordering my parts, taking calls, delegating and in a nutshell keeping our fleet running safely.