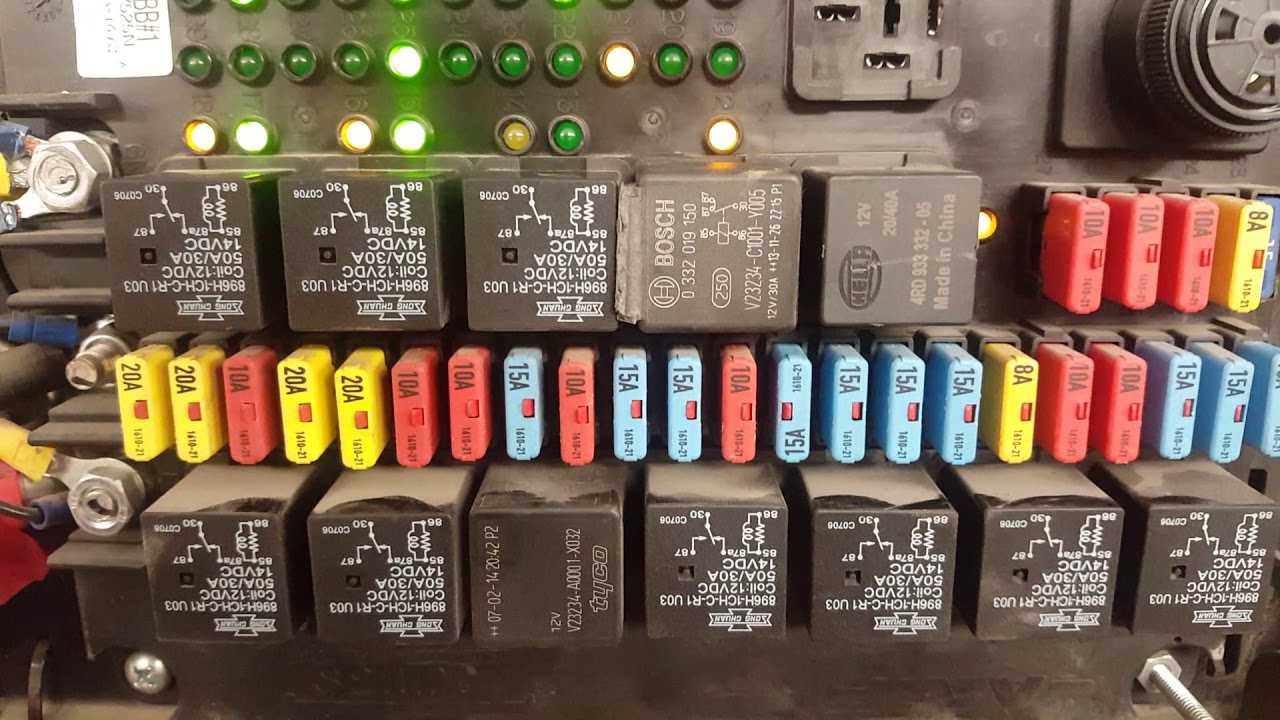

Electrical troubleshooting can be a breeze once you know the layout. It’s much like any blueprint that details the operating system. With this Thomas HDX rear engine pusher model the engineers were very kind developing an easy to use electrical circuit board system that offers the details of each board on the access door. I’m thankful for this as you can see in the video it makes troubleshooting much easier compared to other vehicles I have experienced with electrical issues.

The first place to start is what component has failed to run. In this case the driver’s defrost motor which is extremely important for visibility. I really didn’t have to mention that but in reality this bus would be out of service on a frosty day. The source is always the first step with anything that does not work. In this case I will check for battery power via the 15 amp fuse that feeds the defrost motor relay. It passed and you probably noticed it is a type of fuse that can be reset.

You could definitely go over this step and check for power right at the defrost motor but would if the motor was OK and there was an open in between the circuit. You would have wasted labor disassembling the parts to get access to the motor. So for troubleshooting purposes starting with the source is the best way to go. Fuse is good, now I check for power to the defrost motor relay which is the amber LED. With the ignition key on of course there is power to the relay and also power out with a lit up green LED.

So we know the fuse F1 and relay #12 are working properly. Now it’s worth the time to remove the defrost motor and check for battery power at the connector. As you saw in the video there is power to the motor so replacement is necessary. Now I can tell you that these motors have a high failure rate due to the blower shaft bearings that dry up and cause a high resistance to rotation. First glance these circuit boards look complicated but once you study the legend on the access door it’s not hard at all to do an accurate diagnosis.

I hope this example helped out. This same procedure can be used for any body electrical problem which includes motors, lights and other related accessories. Until next time thank you for reading this article and please comment with your questions.